CNP Fit Testing and HSE INDG 479

The performance of tight-fitting facepieces depends on achieving good contact between the wearer’s skin and the face seal of the facepiece. One type or size of RPE facepiece does not fit everyone and an inadequate fit significantly reduces the protection provided to the wearer. So fit testing ensures the equipment selected is right for each individual and, as the name suggests, fits correctly.

Controlled negative pressure (CNP) technology has been in use for decades and, in terms of the HSE in the UK, is fully referenced as a fit testing method in their INDG 479 guidance on fit testing. The BSIF’s Fit2Fit RPE Fit Test Provider Accreditation Scheme, supported by the HSE, also offers a dedicated companion guidance document on Quantitative CNP technology.

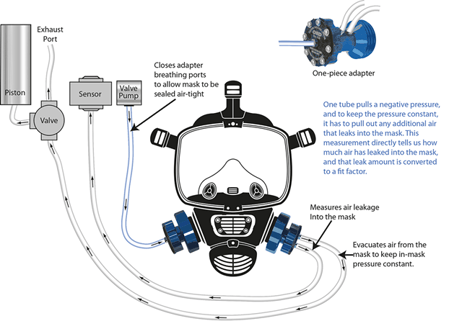

CNP technology is the fastest-growing quantitative method of fit testing for re-useable half- and full-face respirators globally. It works by pulling a negative pressure inside the mask and, to keep that pressure constant, it must pull out any additional air that leaks into the respirator. This measurement tells you how much air has leaked into the respirator and this is converted into an HSE-defined fit factor.

Quantitative fit testing (QNFT) provides a numerical measure of the seal against the wearer’s face, called the quantitative fit factor (QNFF), which is calculated by the fit test equipment and indicates a pass or fail.

It is widely accepted that the average adult breathing rate for resting is approximately 6 litres/min or 12 breaths/min and during exercise is between 50-100 litres/min or 30/40 breaths/min. But every individual is different, so CNP technology challenges the respirator rather than the person. Additionally, it is able to replicate conditions more extreme than it’s possible to achieve by movement or breathing in a fit test.

The HSE INDG 479 guidance uses scientifically calculated modelled breathing rates for CNP fit testing to challenge different mask types at a constant challenge pressure (CP) and inspiratory flow rate (IFR):

|

Mask type |

Challenge Pressure |

Inspiratory Flow Rate |

|

Half mask |

0.58“ H2O |

53.8 Litres/min |

|

Full-face mask |

1.0“ H2O |

55.8 Litres/min |

|

SCBA |

1.5“ H2O |

93.1 Litres/min |

Using the challenge pressure and flow rates specified in HSE INDG 479, CNP technology applies a scientifically established higher, and therefore more rigorous, breathing rate consistently for every fit test, so it removes any variables within the test process.

The fit test exercises for the CNP method are set out in HSE INDG 479 guidance and the fit factors are measured at the end of each exercise, while the subject is stable and holding their breath. During these exercises, the ability of the respirator to reseat is being checked, which is a critical aspect of respirator fit. In real life, users will knock and unseat respirators while wearing them at work. Leaks will occur during this type of extreme events, so CNP challenges and checks the fit again following each activity.

CNP technology does not perform fit tests on disposable facepieces (FFP range), as they don’t have the structural integrity to withstand the negative pressure created by the technology.

With the huge increase in use of both medical and disposable FFP respirators during the COVID-19 pandemic, an increasing number of employers and government institutions are also now switching to reusable respirators for environmental reasons.

Ocean Conservancy Vice President of Conservation, Doug Cress, told the BBC in an interview in July 2020 that there are an estimated 129 billion face masks being disposed of globally every month during COVID-19. Recycling face masks in the UK is problematic as they cannot be processed through conventional recycling facilities and, if buried in landfill, they will take 450 years to break down. A significant number of masks will also be disposed of improperly and end up in the ocean, exacerbating an already grave crisis in terms of plastic pollution and threat to wildlife.

Advantages of CNP Technology

Firstly, not all respiratory hazards are particles. Gases and vapours can also cause toxic breathing environments, so by using air as the challenge agent you are showing that if air can get inside the mask, gases and vapours potentially can too.

CNP technology is not environmentally dependent, so it can test anywhere where air is present, indoors or outdoors in clean or dirty air. It is ready to use immediately following a simple daily calibration.

With no need to create a specifically controlled environment, employers have the option to take the portable unit out to the workforce and perform fit testing in the field, which is very time efficient.

CNP technology requires no consumables so the cost of ownership is significantly lower, and maintenance far simpler.

Anyone who has recently eaten, smoked or used an e-cigarette can still be tested with CNP, as the contamination effect of food, smoking or vaping does not interfere with the ability to measure for leaks using controlled negative pressure.

For more information on CNP fit testing technology in the UK and Ireland, or to arrange a demonstration of the Quantifit Fit Tester, contact Shawcity.

Tel: 01367 899419

Email: solutions@shawcity.co.uk